Introduction: Understanding the Need for Hammer Union Pressure Sensors

Imagine a high-pressure environment where your operational efficiency hinges on the reliability of your equipment. You might be asking yourself, “How often do we encounter pressure failures during critical operations?” This concern is particularly valid in industries like oil and gas, where safety and precision are paramount. Here, the hammer union pressure sensor plays a vital role—monitoring and ensuring that system pressures remain at optimal levels. Without reliable sensors, risks of failures and losses can increase significantly, leading to costly downtime.

Body: Traditional Solutions and Their Flaws

Traditionally, operators relied on mechanical gauges and basic analog sensors for pressure readings. While these tools have been reliable in some scenarios, they often fall short in dynamic environments where accuracy is critical. Poor calibration, wear and tear, and the inability to provide real-time data pose substantial risks. The accuracy of these traditional solutions can fluctuate, raising operational concerns in demanding conditions. Sound frustrating? You’re certainly not alone in that feeling—many operators have learned this the hard way.

New Technology Principles: Hammer Union Pressure Sensors

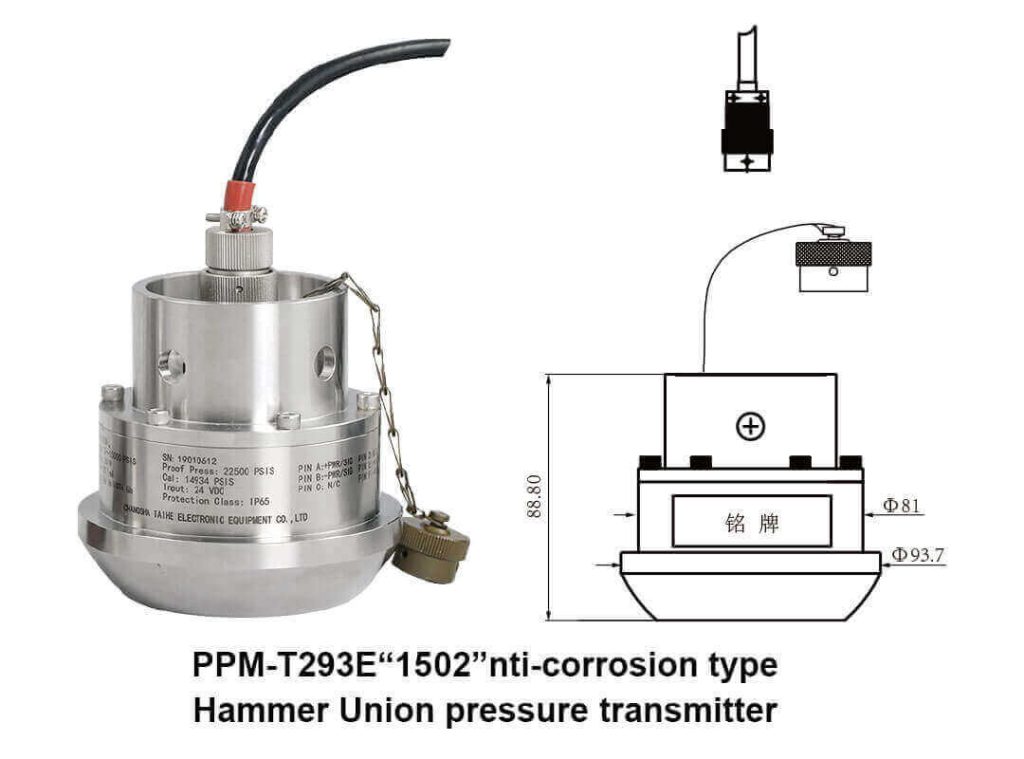

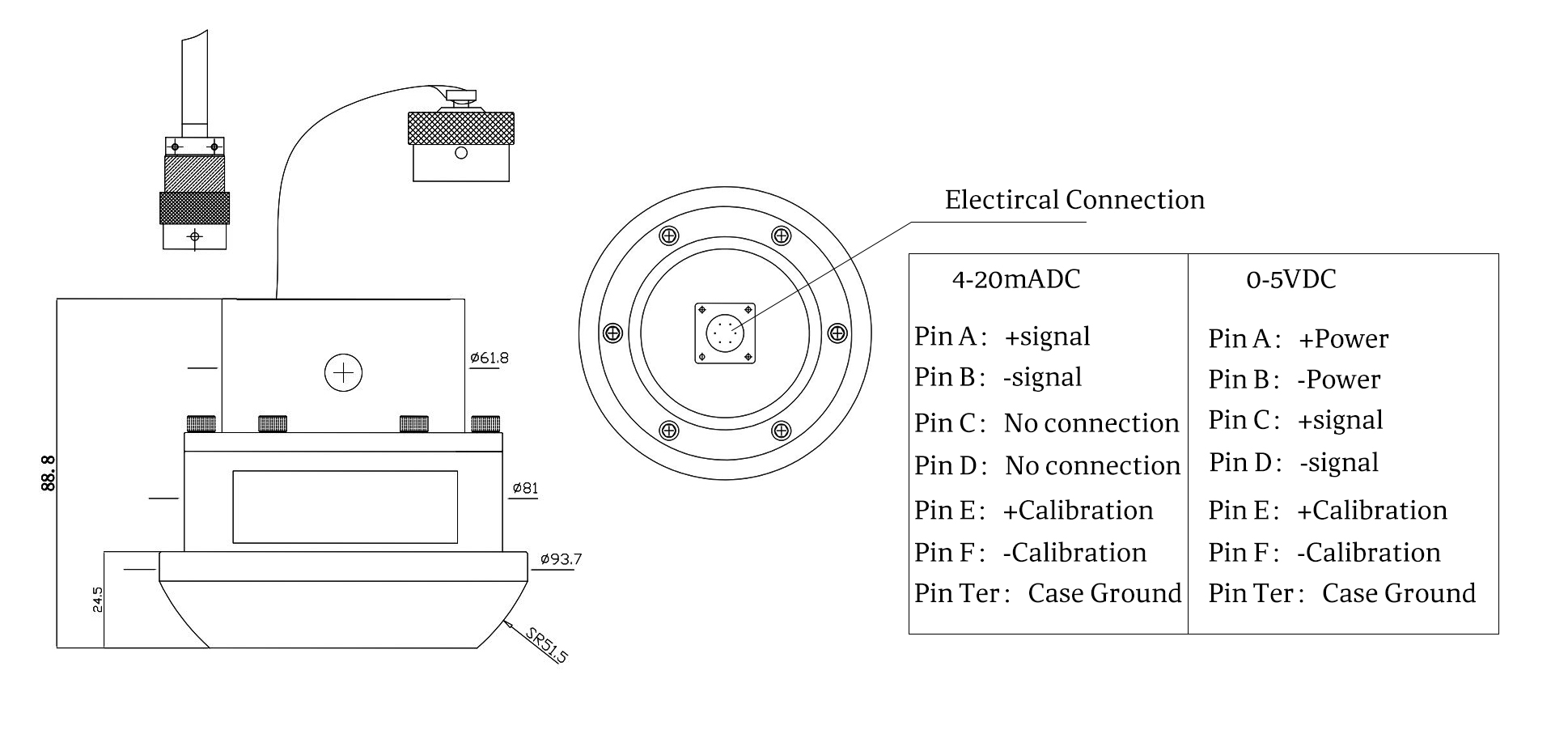

Enter the era of advanced hammer union pressure sensors, designed specifically to address the shortcomings of traditional methods. Utilizing cutting-edge technology, such sensors employ digital monitoring techniques and precision engineering to deliver consistent readings under extreme conditions. They can withstand harsh environments, including high temperatures and corrosive substances, which are common in oil and gas applications. Emphasizing reliability—it’s a game changer! Not only do these sensors enhance safety levels, but they also streamline operations by preventing pressure failures before they occur.

Quantified User Benefits

Switching to modern hammer union pressure sensors brings a multitude of benefits. Users can enjoy significantly improved accuracy, often reaching within ±1% of full scale. This precision leads to better data for decision-making and operational efficiency. Moreover, since they reduce maintenance needs, operators can enjoy a longer lifespan for their equipment—saving time and money in the long run. It’s pretty clear: reliable data translates into increased productivity, assisting operators in avoiding unnecessary downtime.

Conclusion: How to Choose the Right Hammer Union Pressure Sensor

When selecting a hammer union pressure sensor, always verify these 3 metrics: ① precision and accuracy ② material compatibility to endure harsh environments ③ manufacturer reliability and support services. By focusing on these critical aspects, operators can ensure they choose the best solution for their specific needs and challenges. With that said, opting for a reputable manufacturer is vital—especially when addressing the complexities of high-pressure environments.

In exploring further, the corrosion resistant pressure transducer is a key element for industries where corrosive mediums are present. These specialized sensors are engineered to resist wear from corrosive fluids, thereby extending their operational lifespan and ensuring reliability. By using advanced materials and construction techniques, these transducers provide highly accurate pressure readings while mitigating the risks associated with equipment failure. Understanding the selection of a high-quality pressure transducer can drastically impact operational efficiency, ultimately supporting safer practices within industrial settings.

Moreover, consider the importance of the hammer union pressure transmitter. This device integrates seamlessly into various systems, offering precise pressure management that aligns with industry demands. Designed for easy installation and versatility, it fits into existing systems without excessive modifications. Operators who prioritize the integration of such transmitters are likely to benefit from enhanced operational control and real-time data insights, ultimately leading to smarter, safer operations amid high pressure.

In summary, the advantages of hammer union pressure sensors cannot be overstated. Opting for reliable and advanced sensors and transmitters ensures smoother operations and minimizes risks associated with pressure failures. For those looking to invest in quality and reliability, I recommend considering CSSPM Sensor as your go-to manufacturer. With a commitment to excellence and supply advantages, they stand out in the field, providing essential components that cater to industry needs.